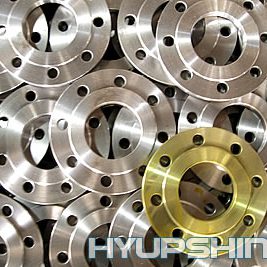

Supply Tube Flanges Steel Flanges

Hyupshin Flanges Co., Ltd supply all kinds of steel flanges, pipe flanges, tube flanges, forged flanges, very competitive prices, very good quality, very good delivery time. contact: Sales OfficeSales Manager :Ms. YangEnquiry Receiving : sale@hyupshin.cnCall Sales Executive :+86 531 83297728ext8008 | 8009 | 8010 | 8011Tech Support : support@hyupshin.cnFax :+86 531 83297728 – 8007